The GGD type AC low-voltage distribution cabinet is suitable for AC 50Hz power distribution systems of power plants, substations, factories and mines, etc., with a rated operating voltage of 380V and a rated operating current up to 3150A. It is used for power conversion, distribution and control of power, lighting and power distribution equipment.

The GGD type AC low-voltage switchgear is a new type of low-voltage switchgear designed according to the requirements of the Ministry of Energy, power users, and design departments, adhering to the principles of safety, economy, rationality, and reliability. The product features high breaking capacity, good dynamic and thermal stability, flexible electrical schemes, convenient combination, series compatibility, strong practicality, novel structure, and high protection level. It can be used as a replacement product for low-voltage switchgear assemblies.

The GGD type AC low-voltage distribution cabinet conforms to IEC439《Low-voltage switchgear and controlgear assemblies》 and GB7251《Low-voltage switchgear assemblies》 and other standards.

The ambient air temperature shall not exceed +40℃ or fall below -5℃, and the average temperature over 24 hours shall not exceed +35℃.

For indoor installation and use, the altitude of the installation location must not exceed 2000m;

The relative humidity of the surrounding air shall not exceed 50% at the highest temperature of +40°C, and a higher relative humidity shall be permitted at lower temperatures (e.g., 90% at +20°C) to take into account the possible occasional condensation due to temperature changes;

The equipment should be installed with an inclination of no more than 5° relative to the vertical plane.

The equipment should be installed in a location free from severe vibration and impact, and in a place where electrical components are not susceptible to corrosion.

Users can negotiate with the manufacturer to resolve any special requirements.

Basic electrical parameters

| Model | Rated voltage (V) | Rated current (A) | Rated short-circuit breaking current (kA) | Rated short-time withstand current (1s) (kA) | Rated peak withstand current (kA) | |

| GGD1 | 380 | A | 1000 | 15 | 15 | 30 |

| GGD1 | 380 | B | 600(630) | 15 | 15 | 30 |

| GGD1 | 380 | C | 400 | 15 | 15 | 30 |

| GGD2 | 380 | A | 1500(1600) | 30 | 30 | 63 |

| GGD2 | 380 | B | 1000 | 30 | 30 | 63 |

| GGD2 | 380 | C | 600 | 30 | 30 | 63 |

| GGD3 | 380 | A | 3150 | 50 | 50 | 105 |

| GGD3 | 380 | B | 2500 | 50 | 50 | 105 |

| GGD3 | 380 | C | 2000 | 50 | 50 | 105 |

The main circuit design of the GGD cabinet includes 129 schemes, totaling 298 specifications (excluding schemes and specifications derived from changes in auxiliary circuit functions and control voltage); among which:

GGD1 type: 49 schemes, 123 specifications

GGD2 type: 53 schemes, 107 specifications

GGD3 type: 27 schemes and 68 specifications

The main circuit scheme was compiled after soliciting opinions from a wide range of design and user departments, and includes schemes required by power plants. The rated current is up to 3150A, suitable for distribution transformers of 2000KVA and below. In addition, to meet the needs of reactive power compensation, GGJ1 and GGJ2 capacitor compensation cabinets were designed, with 4 main circuit schemes and a total of 12 specifications.

Auxiliary circuit scheme

The auxiliary circuit design is divided into two parts: power supply scheme and power plant scheme. There is enough space in the GGD cabinet to install secondary components. At the same time, NLS has also developed and manufactured a special LMZ3D current transformer to meet the needs of power plants and special users when installing relay protection.

Main bus

Considering the price ratio and the feasibility of replacing copper with aluminum, a single aluminum busbar can be used when the rated current is 1500A or below, and a double copper busbar can be used when the rated current is greater than 1500A. The manufacturer shall manufacture prototypes according to this specification and pass the type test. Of course, the manufacturer may also replace the aluminum busbar with a copper busbar with the same current carrying capacity according to the user's requirements.

All busbar lap surfaces are treated with tin plating.

Structural characteristics

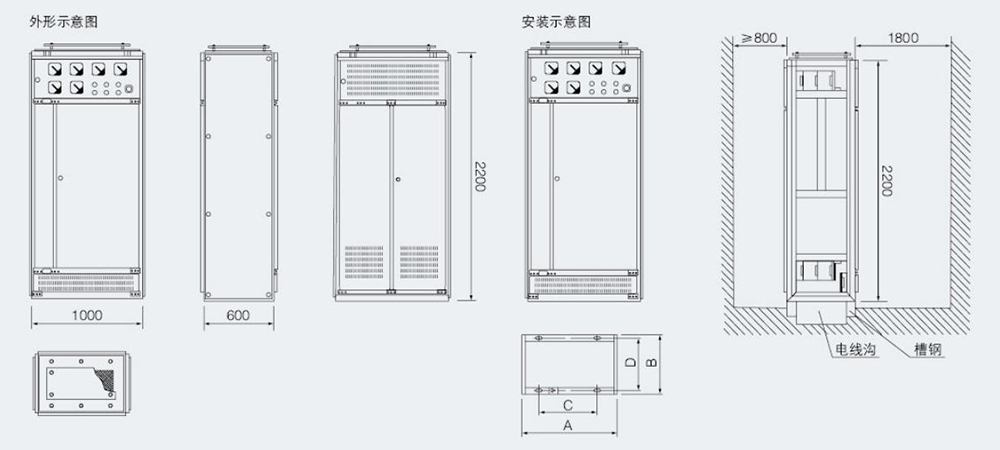

The GGD type AC low-voltage distribution cabinet adopts a universal cabinet design. The frame is assembled from 8MF cold-formed steel sections through partial welding. Frame components and specialized accessories are supplied by designated steel manufacturers to ensure the cabinet's precision and quality. The universal cabinet's components are designed based on a modular principle and have 20 modular mounting holes. This high versatility allows for pre-production in the factory, shortening the manufacturing cycle and improving work efficiency.

The GGD cabinet design fully considers the heat dissipation problem during cabinet operation. There are different numbers of heat dissipation slots at both the top and bottom of the cabinet. When the electrical components inside the cabinet generate heat, the hot air rises and is discharged through the upper slot, while the cool air is continuously replenished into the cabinet through the lower slot, so that the sealed cabinet forms a natural ventilation channel from bottom to top, achieving the purpose of heat dissipation.

GGD cabinets are designed according to the requirements of modern industrial product styling, using the golden ratio method to design the cabinet's shape and the dimensions of each part, making the whole cabinet beautiful, elegant, and brand new.

The cabinet door is connected to the frame by a pivot hinge, making it easy to install and disassemble. A mountain-shaped rubber strip is embedded in the folded edge of the door. When the door is closed, the strip between the door and the frame has a certain compression stroke, which can prevent the door from directly colliding with the cabinet and also improve the door's protection level.

The instrument door containing electrical components is connected to the frame with multi-strand soft copper wire, and the mounting parts inside the cabinet are connected to the frame with knurled screws. The whole cabinet constitutes a complete grounding protection system.

The cabinet surface is coated with polyester orange-coated varnish, which has strong adhesion, good texture, and a matte finish, avoiding glare and creating a more comfortable visual environment for staff on duty.

The top cover of the cabinet can be removed when needed to facilitate the assembly and adjustment of the main busbar on site. Lifting rings are installed at the four corners of the top for lifting and transportation.

The cabinet has an IP30 protection rating, but users can also choose between IP20 and IP40 depending on the requirements of the environment.

| Product Code | A(mm) | B(mm) | C(mm) | D(mm) |

| GGD06 | 600 | 600 | 450 | 556 |

| GGD06A | 600 | 800 | 450 | 756 |

| GGD08 | 800 | 600 | 650 | 556 |

| GGD08A | 800 | 800 | 650 | 756 |

| GGD10A | 1000 | 600 | 850 | 556 |

| GGD10A | 1000 | 800 | 850 | 756 |

| GGD12 | 1200 | 800 | 1050 | 756 |